Material

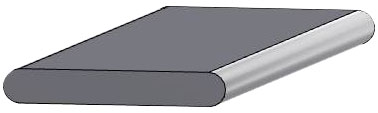

Our machines can handle a wide variety of materials and contours

Stainless Steel

0,05-5 mm

Strip thickness

2-1000 mm

Strip width

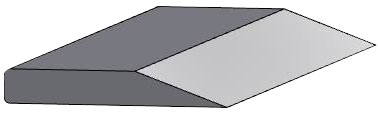

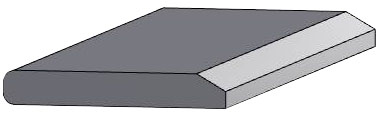

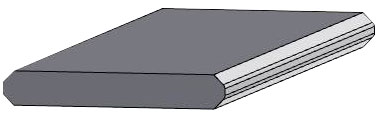

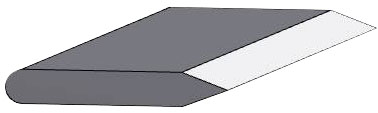

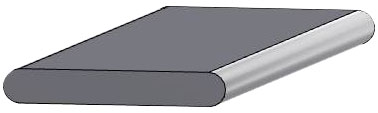

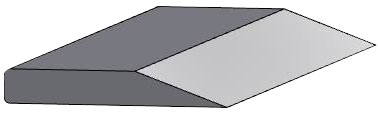

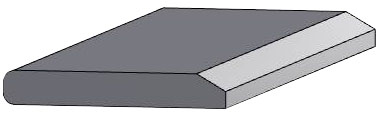

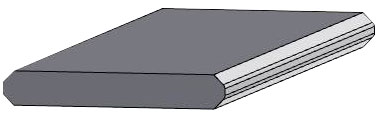

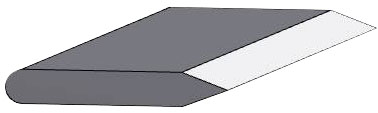

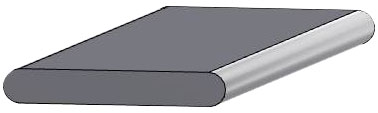

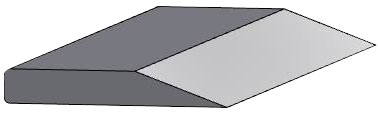

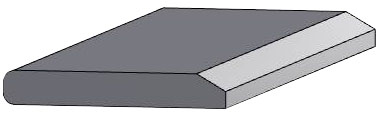

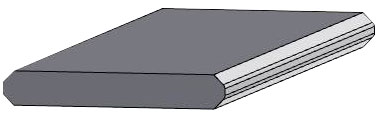

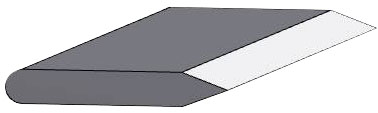

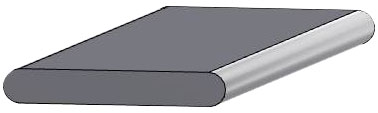

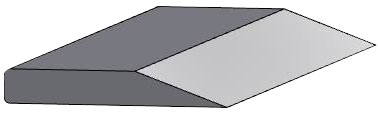

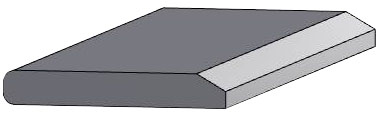

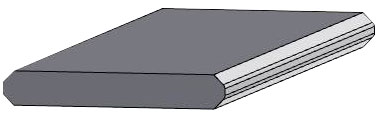

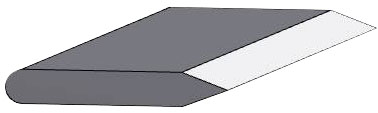

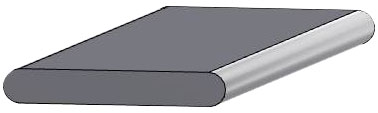

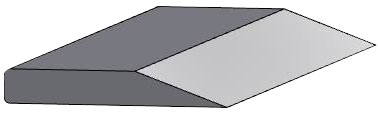

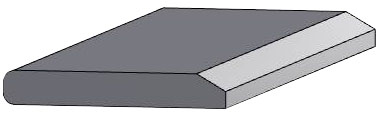

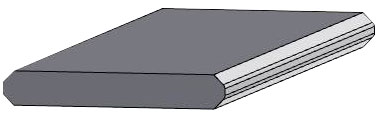

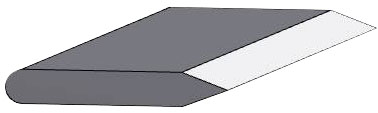

Contours

Steel

0,05-5 mm

Strip thickness

2-1000 mm

Strip width

Contours

Copper alloys

0,05-5 mm

Strip thickness

2-1000 mm

Strip width

Contours

Aluminium alloys

0,05-5 mm

Strip thickness

2-1000 mm

Strip width

Contours

Bimetal

0,05-5 mm

Strip thickness

2-1000 mm

Strip width

Contours

Dimensions

The strip width and strip thickness of the products our Strip Edge Trimming machines can handle are unsurpassed.

Strip width

2-1000 mm

Steel

Stainless Steel

Copper alloys

Aluminium alloys

Bimetal

Strip thickness

0,05-5 mm

Steel

Stainless Steel

Copper alloys

Aluminium alloys

Bimetal

Technology

We have decades of experience in the manufacturing of strip-edge trimming machines which consist of:

- Uncoiler and recoiler with traverse unit

- Strip edge trimming unit

- Tension control unit

- Crop shear with standard or C-bolt design

- Chip and scrap removing system

- Deburring station

- Strip width measurement unit

- Contour inspection system ConScan® to display strip contour in real time

Our strip edge trimming technology is being used in a variety of industries, mainly for production of:

- Knives and blades (scalpels etc.)

- Saws, e.g. jigsaws, bandsaws, chain saws or bimetal saws

- Piston rings

- All kind of chains (industrial chains, camshaft drive chains)

- Textile needles as well as for

- Semi-finished product preparation for tubes

About

hpl-Neugnadenfelder Maschinenfabrik GmbH designs and manufactures overall systems for various application fields in the machining of strip edges made of ferrous or non-ferrous metals as well as special materials with metallic or coated surfaces. Whether household or machine blades, cutting tools, surgical instruments, cast or forged tools are required, our strip edge trimming lines represent customer-specific solutions able to machine high-quality strips and pieces. Focused on providing high flexibility to the customer, our strip edge trimming lines can be equipped both with standard tools of the metal industry as well as custom-manufactured tools. The required number of manually or motor-driven adjustable cutting and guide stations is customized to the product specifications.

Our overall systems are designed and manufactured in accordance with the well-established and proven principles of hpl-Neugnadenfelder Maschinenfabrik:

- user-friendly operation and easy handling

- customized automation degree

- ease of repair and maintenance

- short assembly and commissioning times

- minimum set-up times

- solid construction and long lifetime.

Visit our website: www.hpl-group.de